Shrimp hatchery management- Cox’s Bazar, Bangladesh context

1. The Challenge: Complexity in Shrimp Hatcheries

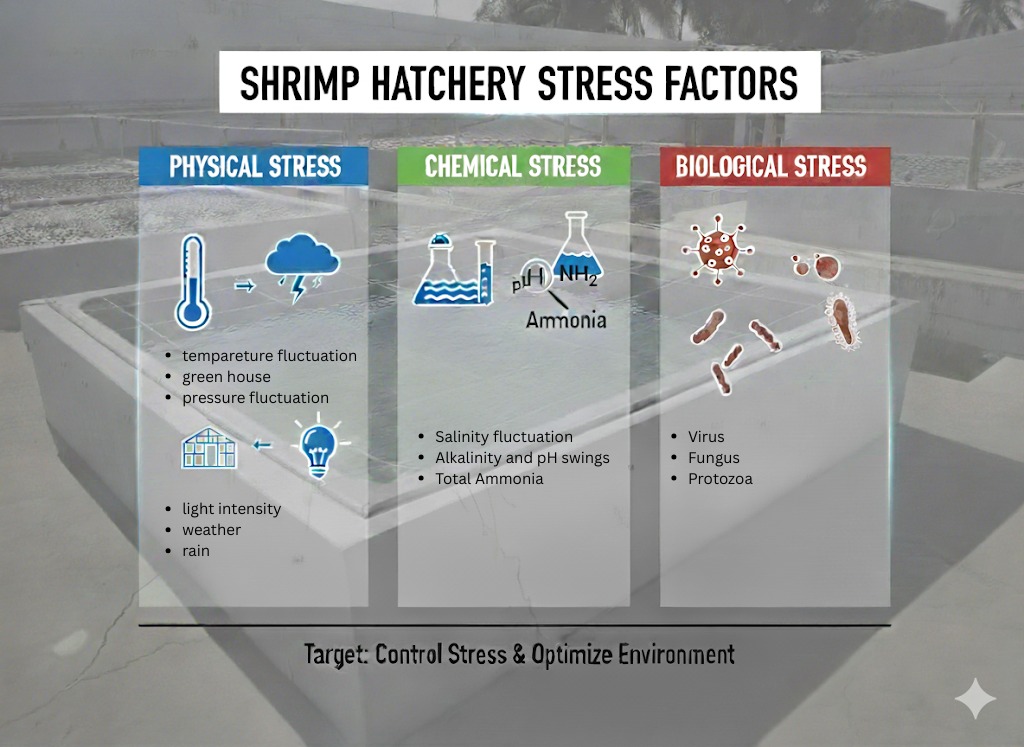

Running a shrimp hatchery means managing a living ecosystem where small fluctuations can create major impacts. A visit by our CEO Professor Alamgir Hossain to Cox’s bazar in September of 2025 revealed that hatchery management have a target to control stress- 3 types of stress that happens usually in hatchery process-

- physical stress (temperature fluctuation, rainfall, greenhouse pressure fluctuation, light etc)

- Chemical stress( sudden salinity fluctuation , alkalinity, pH fluctuation with total ammonia ,NH3 , NH2, )

- Biological stress (virus , bacteria, fungus , protozoa etc )

Environmental Conditions

- Salinity and temperature shifts can trigger outbreaks of luminous bacteria.

- Seasonal pH and alkalinity and temp fluctuations in January February destabilize tanks.

- Surface and bottom water temperatures vary, influencing oxygen levels and shrimp behavior.

Chemical Balance

- Ammonia, nitrite, and nitrate accumulate quickly if not monitored closely.

- Traditional corrective measures, such as water changes, often create sudden fluctuations that shrimp struggle to survive.

Operational Burdens

- Feeding remains largely manual, guided by observation and experience.

- Fry grading is time-consuming and inconsistent, relying on human judgment.

- Weather—rainfall, temperature swings, and seasonal trends—affects multiple parameters but is rarely integrated into decision-making.

- Technicians often find themselves reacting to crises rather than anticipating them.

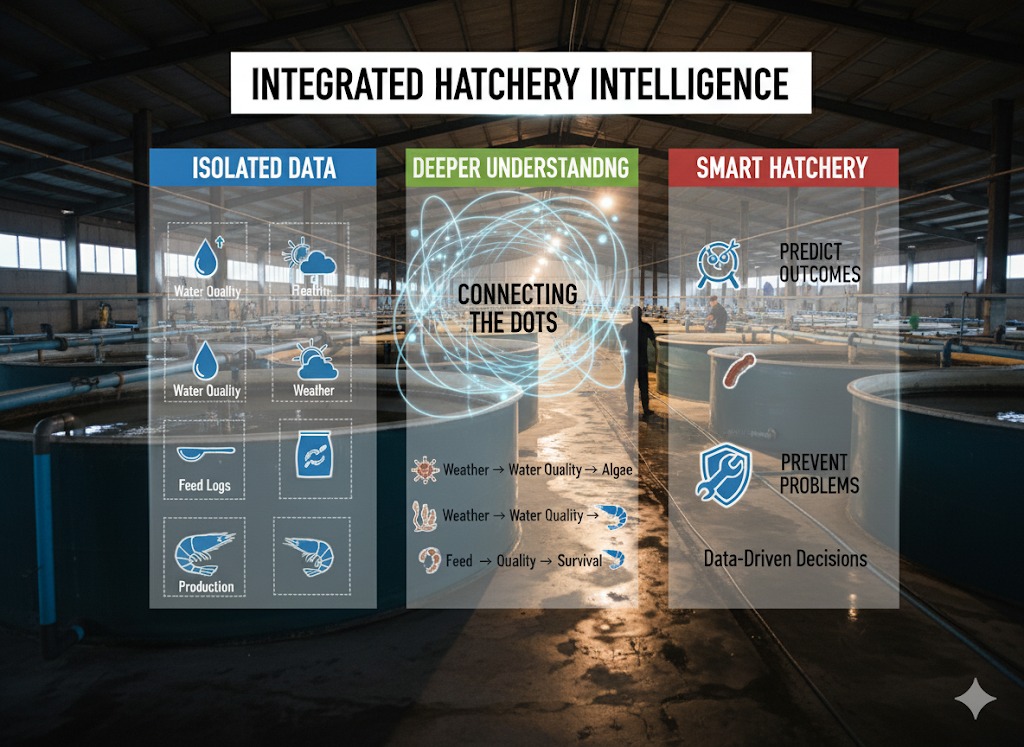

2. The Opportunity: Connecting Data to Action

Hatcheries already gather valuable information: water quality measurements, weather data, feed logs, and production outcomes. But these remain isolated data points. If connected:

- We can understand how weather interacts with salinity, oxygen, and algae growth.

- We can see how feeding, water quality, and shrimp survival are linked.

- We can use data not just to describe problems, but to predict outcomes and suggest preventive actions.

3. Our Solution: An AI-Powered Mobile Platform

We are building a mobile-first AI platform tailored for hatcheries, with a focus on prevention and decision support.

a) Real-Time Monitoring & Alerts

- Continuous tracking of physical parameters: salinity, oxygen, pH, temperature (surface & bottom).

- Weather data (rainfall, air temperature, humidity) integrated into alerts.

- Example: “DO levels dipping faster at night after rainfall dilution—oxygenation risk increasing.”

b) Predictive Risk Scoring

- Mortality risk scores updated daily per batch.

- Explanations highlight key contributors: e.g., rising ammonia, salinity fluctuation after rainfall, or oxygen dips.

c) Actionable Playbooks

- Every alert is paired with a recommended action.

- Example: “Salinity dropped 0.4 ppt after rainfall. Add brine gradually over 12 hours to stabilize. Avoid large water changes.”

d) Optimal Feeding Model

Feeding recommendations are built from multiple layers of data, not just weather:

- Physical parameters: oxygen profiles, ammonia levels, pH, salinity.

- Weather: rainfall, cloud cover, and seasonal temperature.

- Shrimp biology & behavior: nocturnal feeding habits, fry growth stage, appetite signals.

- Historical outcomes: survival and growth data from past batches.

This integration ensures feeding is not only efficient but also safe for water quality and shrimp health.

e) Computer Vision for Fry Grading

- Mobile-based imaging for counting and grading fry.

- Provides objective assessments of homogeneity, weight, and growth stage.

- Reduces reliance on subjective human grading.

4. The Impact: Turning Insights Into Results

With this solution, hatcheries can move from reactive management to proactive prevention:

- Mortality Reduction: At least 10% improvement in survival, directly impacting profitability.

- Water Quality Stability: Balanced interventions that prevent shocks.

- Smarter Feeding: Optimized feeding schedules that consider weather, water parameters, and shrimp biology together.

- Consistency & Quality: Computer vision ensures uniform fry grading.

- Technician Empowerment: A trusted digital assistant that makes recommendations based on data, not guesswork.

5. The Long-Term Vision: A Digital Nervous System for Hatcheries

Over time, the platform becomes the central intelligence of the hatchery:

- Learning from every batch and improving predictions continuously.

- Benchmarking across multiple hatcheries while preserving privacy.

Using weather, water, and operational data together to create a truly adaptive management system. Instead of reacting to problems, hatcheries become predictive, preventive, and resilient—able to thrive even under challenging conditions.